Automotive

The automotive industry is a key major customer of our technologies and

solutions. We show hereafter some applications and implemented solutions.

Engine blocs inspection on production line

|

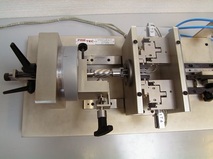

Developed tools to control production line of engines blocs by means of

pneumatic and Electronic measurements systems.

Data processed and visualized with extensive statistics information in line with the quality requirement specific to the car industry. Diameters, depths, axis position, forms, angles, roundness are among the measured features in accurate, fast and cost effective manner. Pictures shown here under are for cars and truck engines blocs. |

Inspection of valves and turbocharges

Inspection of gear shafts

Automatic dynamic inspection of universal joints

|

Fully automatic solution to inspect universal

joints axis shaft with pneumatic and electronic measurement systems. 54

measuring points results in less than one minute:

Handling automatic systems developed to sort the parts out as good or rejected. |